Our company

S.I.T.A. Srl

We have been on the market for over 40 years, leader in the production of UV systems.

SITA was founded in 1982 and has been located in Genoa since then. In 2014, a production site for electronic boards was also opened in Calderara di Reno, Bologna.

A dynamic company, SITA offers a very wide range of products to meet the needs of the Italian and foreign markets. SITA's production, in continuous evolution and expansion, is the result of professionalism and strong synergy on the part of its entire staff. The range of competences, gained in the field of water for human consumption and process water, makes SITA a reference company in the industry, able to offer customised systems as well as sizing and feasibility studies for ad hoc products.

SITAUV for every need since 1982

Our range of UV systems can meet all flow rate (standard ranging from 5 l/m to 4,000 m3/h in a single chamber) and construction requirements. The most common applications for SITA are primary water treatment, swimming pool disinfection, seawater applications, hot water, aquaculture, food and pharmaceutical applications, wastewater with closed manifolds, ozone reduction, free chlorine reduction, TOC reduction, and more.

The lamps used are: low pressure, low pressure amalgam, and medium pressure. We use powers ranging between 12W and 8 kW.

SITA produces about 9.000 UV systems per year.

Our range of filter housings can carry from 3 cartridges to 80 in a single housing. For these units, SITA works closely with its customers to build units that are increasingly tailored to specific needs.

SITA produces about 500 industrial filters annually.

SITA's production of UV plants and steel filter containers is entirely "made in Italy." At our headquarters in Genoa, we design and build our units according to high quality standards. The company's quality was certified ISO9001 back in 1999.

SITA carpentry is equipped with all the latest equipment SITA produces about 9,000 UV systems per year.

Our range of filter housings can carry from 3 cartridges to 80 in a single housing. For these plants, SITA also works closely with its customers to build plants that are increasingly tailored to specific needs.

SITA produces about 500 industrial filters annually.

SITA's production of UV plants and steel filter containers is entirely "made in Italy." At our headquarters in Genoa, we design and build our plants according to high quality standards. The company's quality was certified ISO9001 back in 1999.

SITA carpentry is equipped with all the latest equipment for working with stainless steel. For the construction of our UV units and filters, we start from pipe or sheet metal according to the required diameters.

Our welding process is certified. Welding can be automatic or manual depending on the type of work required. Lathes, automatic drilling machines, tube cutting machines, laser cutting machine are essential for our production process. Another processing step is the passivation and pickling process of steel which is essential to ensure a long life for our equipment.

Finally, polishing and electropolishing should not be forgotten, which not only gives the product its final look but also improves its quality and makes it suitable for many applications. For the construction of our UV units and filters, we start from pipe or sheet according to the required diameters.

Our welding process is certified. Welding can be automatic or manual depending on the type of work required. Lathes, automatic drilling machines, tube cutting machines, laser cutting machine are essential to our production process. Another processing step is the passivation and pickling process of steel that is fundamental to ensure a long life for our equipment.

Finally, polishing and electropolishing should not be forgotten, which not only gives the product its final look but also improves its quality and makes it suitable for many applications.

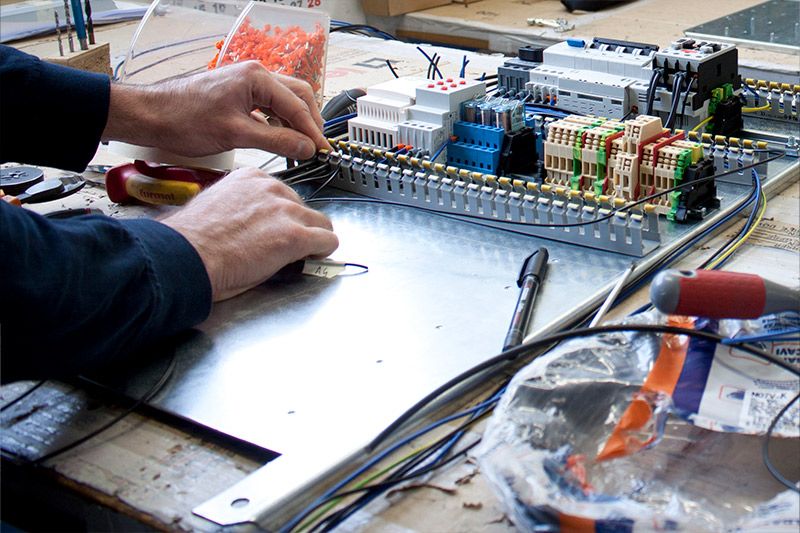

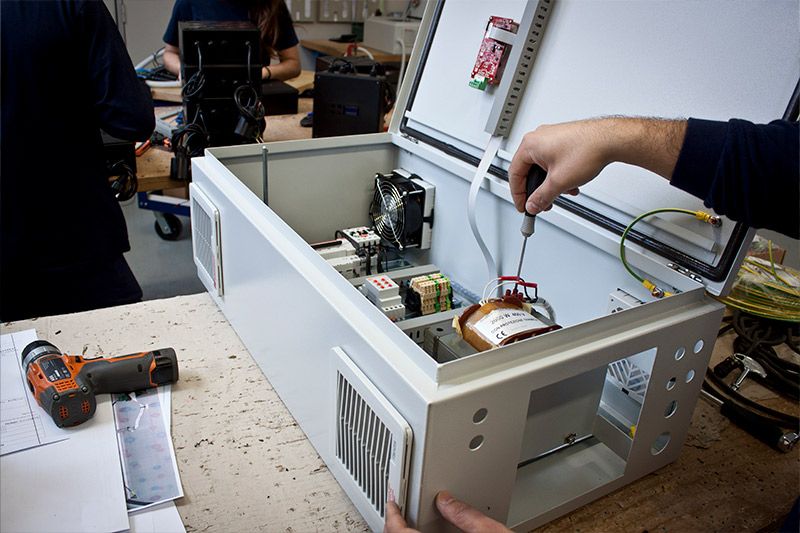

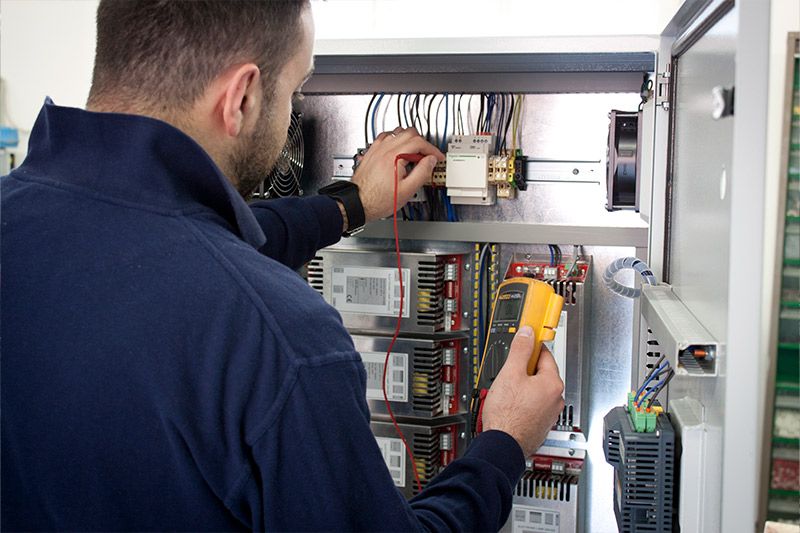

Electrical panels are a key part of UV systems. More and more avant-garde with ever greater needs, they must be able not only to turn on the lamps but also to regulate their power according to the water flow rate or UVC dose required.

The process was born in Bologna, Italy, where SITA's electronics division designs and manufactures the electronic boards, UVC sensors and software needed. In fact, the panels must be able to communicate with other PLCs for perfect integration into the complex water treatment system. While in Genoa, we cable and test the complete panels. We are able to handle power ratings from 10 W to 80 kW. We currently manufacture panels according to CE and UL directives. After final testing, the panels are matched with the UV chambers and the complete system is ready to be placed on the market.